China Starts Up First Nuclear Cogeneration Project—at AP1000 Plant

Credit to Author: Sonal Patel| Date: Tue, 03 Dec 2019 20:53:22 +0000

The post China Starts Up First Nuclear Cogeneration Project—at AP1000 Plant appeared first on POWER Magazine.

China has started up its first commercial nuclear cogeneration system, using two newly operational AP1000 reactors at the Haiyang Nuclear Power Plant to heat 700,000 square meters of housing.

Shandong Nuclear Power Co. (SDNPC), a subsidiary of State Power Investment Corp. (SPIC), and owner of the Haiyang plant, on Nov. 15 said the first phase of the Shandong Haiyang Nuclear Energy Heating Project was formally put into operation.

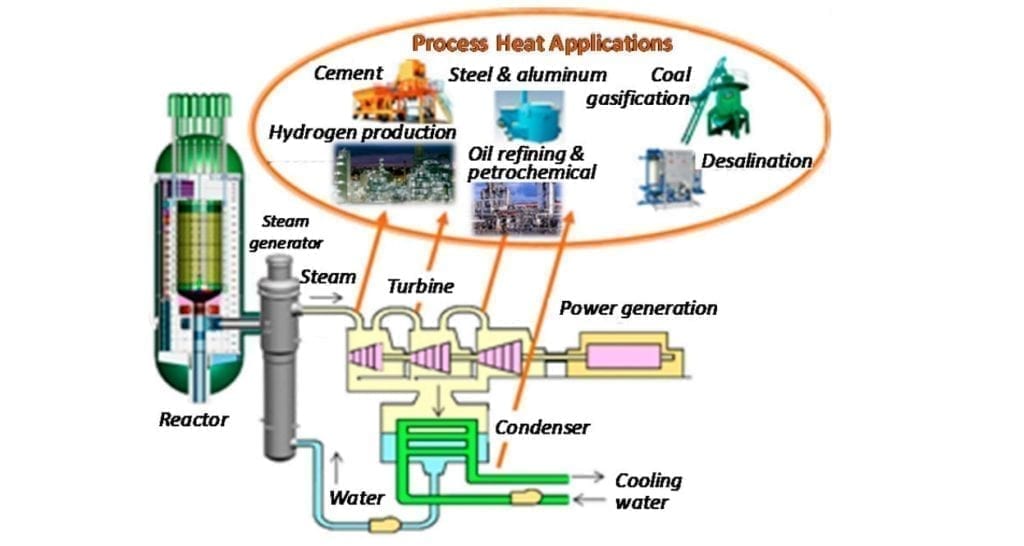

Details about how Haiyang is producing heat are unclear. Generally, in a nuclear cogeneration process, a coolant recovers the thermal energy released by fission in the reactor core. That energy is usually converted into electrical power through a turbine generator, but when heat is part of the final use, it can be used directly for district heating and cooling, process steam, desalination, hydrogen, or steel manufacturing.

How nuclear cogeneration generally provides heat for industrial applications. Source: International Atomic Energy Agency (IAEA)

Vast Expansion Planned for Haiyang Heat Project

The International Atomic Energy Agency (IAEA), which published guidance on nuclear energy cogeneration this September, notes that combined heat and nuclear power is not new, though interest in it is growing. About 43 nuclear reactors around the world generate district heating, most which are in Eastern Europe and Russia; about 17, in Japan, Kazakhstan, and the U.S., desalinate water; and industrial non-electric applications have been achieved at seven reactors in Canada, Germany, India, and Switzerland.

In total, nuclear cogeneration projects around the world have to date accumulated nearly 750 operating years of experience—which compares to 17,000 reactor years of experience for civil nuclear power. Of reactors that today provide district heating, heat power output ranges 5 MWth to 240 MWth, the IAEA says. The total distributed heat power is around 5,000 MWth, according to the IAEA, which corresponds to an average energy withdrawal of less than 5%. “This means that, even if running in cogeneration mode, the primary output of the reactor is still electrical power,” it explained.

The Haiyang project is important for two reasons: It leverages energy from newly constructed third-generation reactors—some of the first AP1000s completed to date; and its success will serve as a blueprint for nuclear energy diversification and a “clean” heat expansion in China, which has 45.6 GW of installed nuclear capacity and has another 11 GW under construction.

As part of the first stage, the project is providing heat to the nuclear plant’s employee dormitory and some residential areas in Haiyang, a coastal city in Shandong province, eastern China, that has a population of about 658,000. No timeline is provided, but SDNPC says a later stage will involve modifications to Units 1 and 2 to expand the heating capacity to 30 million square meters.

SPIC, meanwhile, plans to build four more units at Haiyang, though these will feature a local standardization of the AP1000 design, known as the CAP1000. While Units 3 and 4 received construction approval in December 2015 and construction was slated to begin in 2017, no progress has been reported yet. Unit 1 of the Haiyang plant began operation in October 2018, with Unit 2 following in January, after delays due to equipment problems and the three-year moratorium following the Fukushima accident. Haiyang Units 1 and 2 are currently maintaining “safe and stable operation,” SDNPC said, adding that it expects the annual power generation from the plant in 2019 will reach 20.6 TWh—enough to meet about a third of annual demand by Shandong province’s residential needs.

If the planned units are completed, the Shandong Haiyang Nuclear Energy Heating Project could provide more than 200 million square meters of heating capacity, or a heating radius of about 100 kilometers. That translates to an “annual savings of about 6.62 million tons of standard coal.” Currently, the project saves 23,200 tons of coal, SDNPC said. The company projects that by 2030, Haiyang and other “clean energy heating methods” could replace all coal-fired boilers on the Jiaodong Peninsula.

The on-site heat exchange station at the Haiyang plant. Courtesy: SDNPC

Success at Haiyang could also be adopted by other regions, said Ling Wen, Shandong Province’s deputy governor, at a project “observation” meeting and expert seminar on the “comprehensive utilization of nuclear energy” hosted by the National Energy Administration (NEA) at Haiyang on Nov. 28. At the event, Liu Baohua, NEA deputy director, also noted the official commissioning of the nuclear heating project is a critical part of the country’s new national energy security strategy, which will emphasize nuclear energy diversification. He urged the active promotion of “valuable experience” gained from the project.

Among other projects discussed at the meeting is one that could apply nuclear power for seawater desalination. SDNPC on Oct. 12 announced a partnership with the Haiyang Municipal Government and Zhonglian Energy for nuclear heating and desalination projects. According to the announcement, the partners have already conducted a feasibility study of a large-scale desalination demonstration project.

Officials at the event also noted the heating project did not increase SPIC’s financial burden. Details about costs are also unclear. According to the IAEA, an initial investment is typically required for heat transport and distribution, but it notes, “in many cases, the result is cheaper energy to the consumer.” It adds: “After amortization, nuclear reactor waste heat is the cheapest form of heat.”

Why Nuclear Cogeneration Is So Hot Right Now

The IAEA compiled its guidance report based on a surge in interest in combined nuclear heat and power—both from existing generators and developers of small and medium reactors (of between 300 MW and 700 MW)—owing to some key advantages.

Foremost among them is that cogeneration recovers waste heat—and it could boost a nuclear plant’s energy efficiency to 80%. “The typical conversion efficiency from heat to electricity is 33%. Hence, about two thirds of the fission energy ends up heating the atmosphere or the cooling water,” it explains. “Cogeneration allows use of part, if not all, of the waste heat.” That could offer nuclear energy producers a potentially lucrative source of revenue, an expanded customer base, and better flexibility, because it allows for possible switching between the two outputs depending on market signals and demand.

Yet another advantage the IAEA underscores is that cogeneration could reduce nuclear waste, noting, “Making use of more energy per fission in a cogeneration mode … reduces the quantity of waste generated per unit of energy.”

Significantly, the IAEA says that safety of a nuclear power plant does not rely on the operational performance of a cogeneration heat plant, but it notes “any potential radioactivity transfer through the system up to the main heat transfer line,” is a specific concern. “A good practical way to prevent any radioactive contamination to a heat application system, for example, is to physically isolate the primary loop of the reactor from the main transfer line,” it advises. “This is obviously done in a pressurized water reactor (PWR) as the secondary loop is already an isolated closed loop system serving as a barrier for contaminants. However, in a boiling water reactor (BWR), an additional water loop would be needed between the heat exchanger/condenser at the turbine output and the main heat transport (MHT) line.”

The IAEA says, however, that so far, in district heating systems using nuclear heat, “there has been no identified major issue related to the extraction of heat from a nuclear plant.” Hurdles are generally faced by older systems, which can suffer from high heat losses in generation, transport, distribution, and end-use. However, it concludes that cogeneration may be added to existing plants—and, depending on the site, type of reactor, and proximity to end users, it estimates an existing plant could recoup costs within five years if converted to provide district heat. Generally, “nuclear heat in the form of hot water can be delivered up to 150 [kilometers] away at competitive cost and with a reported loss lower than 2%,” it says.

Still, it suggests cogeneration is more attractive for new small and medium–sized nuclear reactors because these designs incorporate enhanced safety features, they often require smaller investments, pose fewer financial risks, and may be easier to site closer to end-users.

Light water reactors are perhaps best suited to district heating and desalination, owing to their low working temperature range, while high-working temperatures of lead-cooled fast reactors (550C), molten salt reactors (700C to 800C), gas-cooled fast reactors (850C), and very-high temperature reactors (900C to 1,000C) are better suited for industrial process heat and hydrogen production, as well as desalination and district heating when used as cogeneration systems, it says.

The range of potential non-electric applications nuclear cogenerators could exploit is also vast. These include high-temperature steam production to feed industrial processes and hydrogen production. They could “first, upgrade low-quality petroleum resources such as oil sands while offsetting carbon emissions associated with steam methane reforming; second, support large scale production of synthetic liquid fuels based on biomass, coal or other carbon sources; and, third, serve directly as a vehicle fuel, most likely using fuel cells,” the IAEA says. The agency notes it has undertaken activities to help member states explore these opportunities in-depth.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine)

The post China Starts Up First Nuclear Cogeneration Project—at AP1000 Plant appeared first on POWER Magazine.