Much-Watched Reciprocating Engine Hydrogen Pilot Kicks Off at Michigan Power Plant

Credit to Author: Sonal Patel| Date: Wed, 01 Jun 2022 17:32:45 +0000

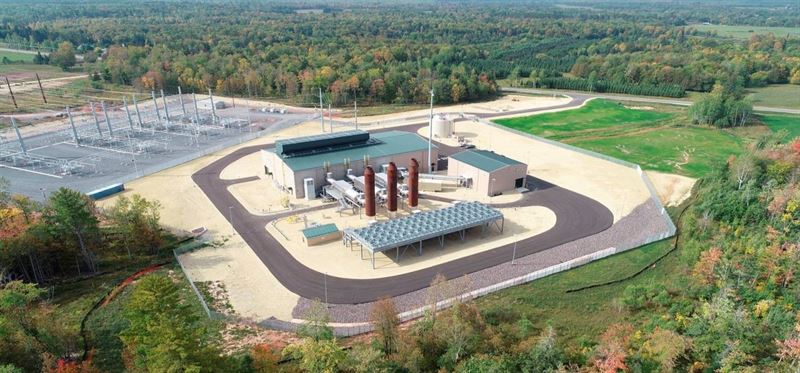

A landmark project to test fuel blends of up to 25% volume of hydrogen mixed with natural gas in reciprocating internal combustion engines (RICEs) has launched at WEC Energy Group’s 56-MW A.J. Mihm power plant in Michigan. If successful, the pilot—one of the first of its kind in the U.S.—could provide key insight into how hydrogen combustion at RICE units could be replicated across the U.S.

A consortium comprising Finnish technology giant Wärtsilä, the Electric Power Research Institute (EPRI), and Burns & McDonnell on May 30 unveiled a contract with Milwaukee-based WEC Energy’s subsidiary Upper Michigan Energy Resources for the fuel testing pilot.

The A.J. Mihm plant, which came online in Baraga Township in March 2019, is outfitted with three 18.8-MW Wärtsilä W18V50SG natural gas-fired, four-stroke, lean burn, spark-ignition units. Only one engine, however, will be selected for the test program. The engine will continue to operate to supply power to the grid as the hydrogen share in its fuel mix will be gradually increased to a maximum of 25% by volume.

According to Wärtsilä, the company’s engines can operate with this level of hydrogen blended “with little to no modification needed”—and even higher levels. However, tests at the A.J. Mihm plant will be restricted to the limit of 25% volume of hydrogen for natural gas systems, which complies with the international equipment standard IEC/EN 60079-20-1, it said.

A Major Demonstration for Wärtsilä

Wärtsilä, which says it has researched hydrogen as a fuel for 20 years, set out to develop a combustion process in its gas engines to achieve 100% hydrogen fuel combustion in May 2020. The company says the development is crucial to its strategy to “future-proof its engine technology in line with the global trend towards decarbonization of the energy and marine markets.” In addition to hydrogen, “other potential renewable fuels are being studied for future applications, and Wärtsilä engines are already capable of combusting 100% synthetic carbon-neutral methane and methanol,” it notes.

The company launched a major test program in July 2021 after carrying out full-scale engine tests at its engine laboratory in Vaasa, Finland, and testing facilities in Bermeo, Spain, to assess the optimum engine parameters for running engines fully on hydrogen. In March, the company began operating two Wärtsilä 34SG engines, a combined output of 11.6 MW, that can run on a 3% hydrogen and natural gas blend (the hydrogen is blended before feeding the fuel mix into the engine) at Keppel Offshore and Marine’s “Floating Living Lab” in Singapore.

This year, notably, the company released its Wärtsilä 32 Methanol engine to the market. In tandem, Wärtsilä has already proven an engine concept running on blends of up to 70% ammonia. A project backed by the Norwegian government for a “long-term, full-scale” test of ammonia as a fuel in a marine four-stroke combustion engine is also underway. Wärtsilä says the full-scale fuel testing program will be integral to paving the way for ammonia engines “to be used in real vessel operations within a few years.” Several shipowners “have shown interest in this possibility,” it notes.

The U.S. project at A.J. Mihm with partners EPRI and Burns & McDonnell is oriented toward securing a foothold for RICEs in the power generating space. “These hydrogen tests reinforce the viability of the internal combustion engine as a future-proof technology that plays a key role in decarbonizing the power industry,” Jon Rodriguez, director of Engine Power Plants at Wärtsilä North America, said on Monday.

“We have long had a focus on creating solutions that enable zero-carbon power generation, and are excited to begin this hydrogen testing project in the USA as a natural next step in developing our products to meet customer needs for a decarbonized future. Our engines already have the flexibility for both balancing the input of renewables into the power system, and baseload generation with a continuously increasing range of fuels,” he added.

The pilot could help Wärtsilä meet ambitious goals to have an engine and plant concept for pure hydrogen operation ready by 2025. For the marine market, the company anticipates having an engine concept with pure ammonia fuel in 2023.

Reciprocating Engines Increasingly Playing a Significant Flexibility Role

But according to other project stakeholders, the Michigan pilot could have a profound impact on broader RICE uptake, given its transition-friendly attributes, and particularly as the conversation about natural gas’s carbon burden gains steam. “Demonstration projects like this one are critical to advancing clean energy technologies needed to meet net-zero goals,” EPRI CEO Arshad Mansoor noted in January. “This project will provide key insights on how this could be replicated throughout the country, providing energy companies with a suite of solutions to reduce carbon emissions,” he added.

Burns & McDonnell, which previously served as the engineering, procurement, and construction contractor for the A.J. Mihm generating units, also suggested results from the pilot would better help inform the still-murky conversation about hydrogen’s future role in the power space. “The interest in hydrogen as an alternative fuel to meet decarbonization goals is a topic we’re constantly talking about and exploring with our customers and we’re eager to see the results of the study,” said Megan Reusser, senior development engineer in the Energy Group at Burns & McDonnell.

Stationary RICE units consist of engines that utilize the expansion of gases and the resultant increased pressure from the combustion of fuel inside one or more confined cylinders to move pistons back and forth in order to rotate a shaft and produce mechanical power. While individual natural gas–fired RICE units are currently limited to 20 MW in size, they can be combined to create larger power plants. RICE units also tend to have higher efficiencies than comparable simple cycle facilities, although they can also emit higher emissions of hazardous air pollutants.

RICEs, however, offer key advantages for grid flexibility given their ability to provide incremental electricity quickly—starting up even when the grid has no power—and operating at partial loads. That’s why, according to the Energy Information Administration (EIA), RICEs have become increasingly important in areas with high shares of renewable electricity generation from wind and solar.

An estimated 5.5 GW of RICE capacity is operational or on standby in the U.S. as of March 2022, a recent EIA dataset suggests. While this comprises less than 1% of the total natural gas-fired power fleet, new RICE installations are catering to markets that are increasingly being saturated with renewables, it suggests.

Source: POWER/EIA-860 (March 2022). View a larger version of the interactive graphic here.

WEC Energy Counting on RICE-Fired Hydrogen as a Viable Option

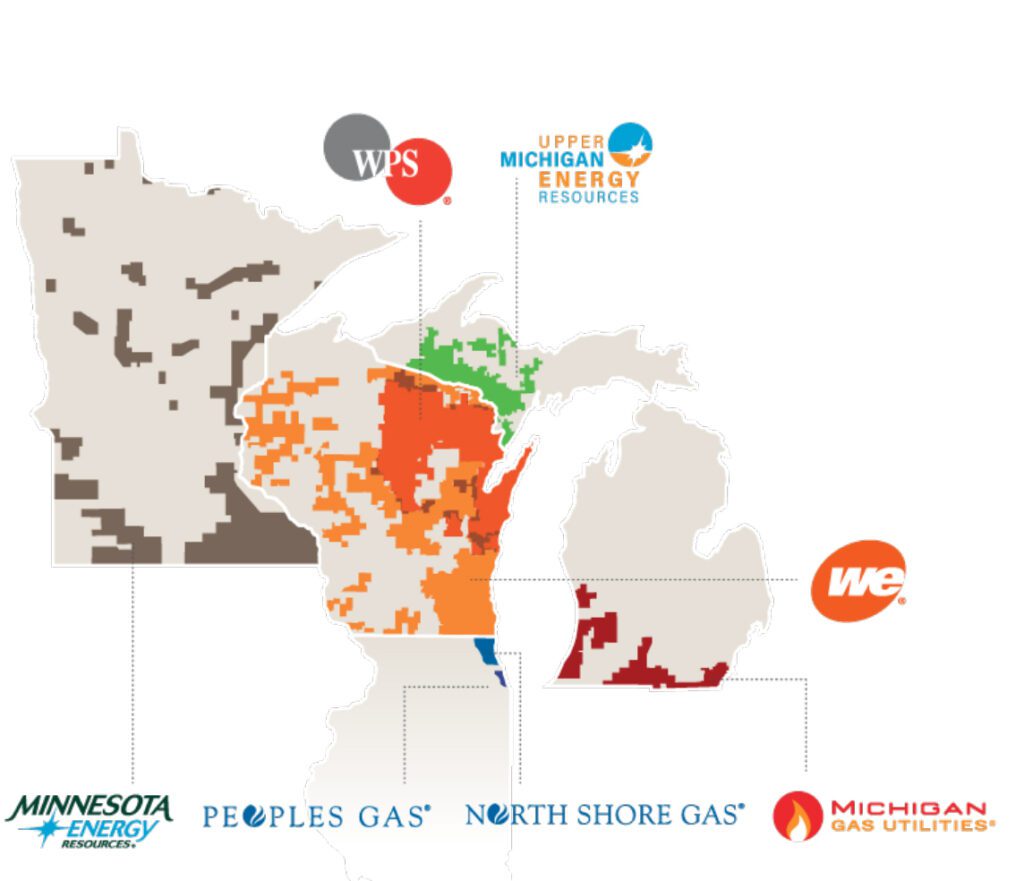

WEC Energy Group, which officially announced the project in January, is counting on the co-firing pilot as a “bridge” to a sustainable future. The company, which has a power generating footprint that serves customers in Wisconsin, Illinois, Michigan, and Minnesota, is grappling with balancing its aggressive environmental goals—including achieving net-zero carbon emissions from power generation by 2050 and net-zero methane emissions from natural gas distribution by 2030—with providing safe, reliable, affordable, and equitable access to power across its footprint.

In a May 12 investor update, the company noted it is facing major near-term retirements of its substantial coal fleet. These include units at two Wisconsin plants: Units 5 through 8 at the Oak Creek plant (a combined 1.1 GW) and two units at the Columbia plant (a total 300 MW) by 2024. By 2030, the company that owns We Energies and We Power expects to use coal only as a backup fuel, but it wants to completely eliminate coal as an energy source by the end of 2035.

“That is on top of the 1,800 MW of coal-fueled generation we retired between 2018 and 2019,” the company notes. “One way we plan to achieve this is to utilize available technology to run super-critical baseload units, including the [2011-completed] new units at the Oak Creek Power Plant, on natural gas.” The company is in addition looking to retire 200 MW of older, less efficient natural gas peaking generation by 2024.

RICE units, along with new solar and storage resources, are also becoming a pivotal part of the company’s transition efforts—which it calls a “Generation Reshaping Plan”—to replace retired capacity from seven coal plants by 2025. The three RICE units brought online at the 56-MW A.J. Mihm power plant were part of a joint project completed in 2019 to install seven Wärtsilä 50SG gas engines for the 128-MW F. D. Kuester power plant in Marquette County, Michigan.

The two RICE plants replaced capacity from We Energies’ 350-MW coal-fired Presque Isle Power Plant in Marquette, Michigan, which was retired in 2019. Another 128-MW RICE project is now under development at Weston Generating Station in Wisconsin. The $170 million project received regulatory approval in March and is targeted to be in service in 2023.

How Reciprocating Engines Compare to Other Technologies

In recent testimony before the Public Service Commission of Wisconsin, John Hagerty, a consultant at Brattle Group, suggested the seven Weston RICE units represented “a cost-effective resource addition” to serve WEC’s load obligations, given “their low all-in operating and capital recovery costs and unique performance capabilities for an increasingly decarbonized system.” These performance capabilities “include the ability to efficiently generate power when needed to meet peak demand and during periods with low or no renewable generation, to ramp quickly up and down in response to unexpected perturbation in the system, and to provide additional resilience benefits,” he said.

Hagerty said WEC subsidiaries Wisconsin Public Service Co. and Wisconsin Electric Power Co. considered multiple resources other than RICEs for replacing the lost coal capacity. These include solar and wind, battery energy storage systems (BESS), as well as combined cycle (CC) turbines, and simple cycle gas combustion turbines (CT).

While solar and wind are carbon-free resources, they are intermittent and not as reliably dispatchable as more conventional dispatchable resources, Hagerty said. BESS resources are meanwhile limited by their duration. Even at a four-hour duration, “they are not a full substitute for dispatchable resources, such as gas-fired resources,” he added.

Compared to CTs, RICEs can start up and ramp up faster, and at a lower cost, and operate more efficiently—burning less fuel per MWh—both at full load and partial load, he testified. While RICE resources tend to have higher capital costs than CTs, multiple units, like the one planned at Weston, can achieve lower capital costs per MW of installed capacity.

And compared to CCs, RICE units are less efficient, but “able to economically cycle off and on more often and to lower load levels without loss of efficiency to meet shorter demand periods when renewable energy resources are not available to produce,” Hagerty explained. “Due to their flexibility and efficiency, RICE units are cost-effective resources to dispatch both on a day-ahead forecasted basis to provide low-cost generation to serve demand and in real-time to mitigate the costs of unplanned changes in system conditions.”

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).

The post Much-Watched Reciprocating Engine Hydrogen Pilot Kicks Off at Michigan Power Plant appeared first on POWER Magazine.