NYPA, GE Successfully Pilot Hydrogen Retrofit at Aeroderivative Gas Turbine

Credit to Author: Sonal Patel| Date: Mon, 26 Sep 2022 15:55:19 +0000

A pioneering GE aeroderivative gas turbine project to demonstrate hydrogen combustion as part of a retrofit at an existing U.S. natural gas power plant has successfully utilized blends of 5% to 44% hydrogen with natural gas—some of the highest volumes of hydrogen blended into a commercially operating gas turbine.

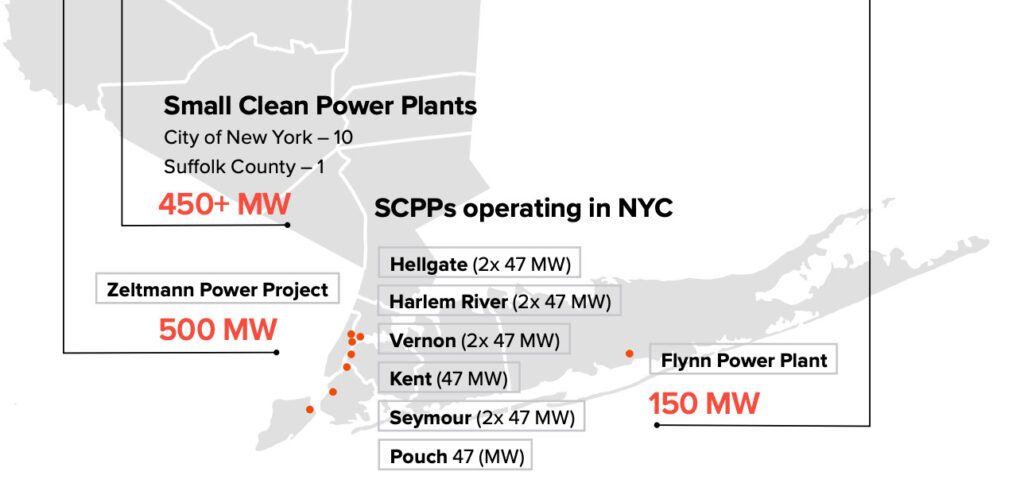

The project spearheaded by New York Power Authority (NYPA), the nation’s largest state public power organization, and GE demonstrated combustion of the hydrogen-natural gas blend on an LM6000 SAC gas turbine at NYPA’s 2001-opened 45-MW Brentwood Small Clean Power Plant in Suffolk County, Long Island, New York.

A key study objective was to demonstrate the gas turbine’s steady state operational capability on hydrogen, as well as to identify an impact on combustion emissions on the LM6000 gas turbine’s outlet emissions, including carbon dioxide (CO2), nitrogen oxide (NOx), and carbon monoxide (CO). Results of the successful test, unveiled on Sept. 23 by project partners the Electric Power Research Institute (EPRI) and GTI Energy, which worked under the research groups’ 2020-launched Low-Carbon Resources Initiative (LCRI), will be pivotal for exploring hydrogen integration at aeroderivative gas turbine plants, which are widely used to provide peaking power, project partners said.

But while the project represents one of the first utility-scale hydrogen blending projects at an existing gas plant in the U.S., it also unveiled several significant challenges that suggest hydrogen combustion is still a long way from practical implementation at a competitive gas power plant.

At Brentwood (Figure 1), which operates in the New York Independent System Operator (NYISO) market, those challenges include a lack of access to the volume of hydrogen required to run the plant, limited industry experience to run the plant on blended hydrogen fuel, and restrictive code requirements. That’s why for now, NYPA does not plan to apply technology learning from the pilot to continue the project at Brentwood or any of its other gas-fired power plants, the organization told POWER on Friday.

A First Crucial Step to Assess a Decarbonization Pathway

The project’s learnings will still, however, play an important role as intended in informing stakeholder discussions about the feasibility of hydrogen power. A key benefit has been to provide insight, said Neva Espinoza, EPRI vice president of Energy Supply and Low-Carbon Resources. LCRI is determined to accelerate development and demonstrate low-carbon technologies that will be needed to help private companies and governments achieve increasingly ambitious decarbonization goals by 2050, she noted. “As industry and government seek innovative energy solutions, NYPA’s hydrogen blending demonstration is uncovering new insights with implications well beyond New York,” she said.

The Brentwood project stems from a July 2021 effort New York State launched to evaluate hydrogen’s potential role in displacing fossil fuels from power generation as it pursues an ambitious target to reduce its carbon emissions 85% by 2050. The state is also looking to achieve mandating a zero-emission electricity sector by 2040, and get to 70% renewable energy by 2030, noted NYPA Interim President and CEO Justin E. Driscoll. The pilot project, meanwhile, aligns with NYPA’s strategic vision priority to decarbonize its natural gas plants by 2035 without sacrificing the reliability of the electric system.

NYPA, a self-financed public power entity, owns 6.6 GW of generating capacity, 1.2 GW of which comes from gas and oil–fired power plants that operate in NYISO. Brentwood is part of NYPA’s “Small Clean Power Plants,” portfolio (Figure 2), which comprises 11 aeroderivative gas plants the entity opened in 2001 to bolster New York’s energy security.

Driscoll told POWER on Friday NYPA’s internal goal is now to retire its gas assets by 2035, five years before the state’s goal of 2040. The Brentwood hydrogen retrofit project “was really just to inform others in the industry and academia to learn whether this could be done, how the plant would tolerate blending, and what the effect on emissions would be,” he said.

As a public power company that is committed to progress, NYPA is “leading the way in New York by piloting new technologies that can help accelerate New York State’s clean energy transition and inform the power industry so that we can move toward a carbon-free economy,” he explained. “Decarbonizing the power sector will require a collaborative, multi-pronged approach, including the use of new technologies and additional renewable power resources.”

However, NYPA is “committed to retiring those plants whether hydrogen would play a role or not,” Driscoll said. “We don’t have any current plan to utilize hydrogen in the transition of those plants. We’re certainly not ruling anything out, but we have no apparent plan to take that learning from this study and apply it to our gas assets. NYPA is “more focused on battery storage solutions,” Driscoll said. NYPA’s plans to retire the plants stem from a recent collaborative study, which demonstrated that the frequency and duration of its aeroderivative fleet’s run times are projected to decline, allowing for the possibility of full replacement with 4-hour battery storage at each individual site, he said.

A Pioneering Project in Its Own Right

As Alan Ettlinger, senior director of Research, Technology Development & Innovation at NYPA, told POWER, the pioneering project’s more significant function was to serve as a preliminary test bed to explore hydrogen combustion, a much-hyped pathway to decarbonize gas power. The cross-cutting industry consortium it convened will likely continue to apply lessons learned to further future initiatives, he said.

While New York in July tasked NYPA with leading the hydrogen combustion pilot, GE, as the LM6000’s original equipment maker, supplied a hydrogen/natural gas blending system and supported the project’s planning and execution. LCRI, led by EPRI, assisted with project design and technical evaluation. Other partners include Sargent & Lundy, the Brentwood plant’s original architect engineer, which served as engineer of record for the project. Airgas, an Air Liquide company, supplied the renewable hydrogen for testing, sourcing it from Air Liquide’s facility in Bécancour, Québec, which is powered by 99% renewable energy. Fresh Meadow Power, developed the piping system that delivered the hydrogen to the GE-designed mixing skid and, ultimately, into the turbine.

Planning—from initial concept to implementation—took “a little bit over a year,” including months of construction with supply chain delays and specialty valves and components, and months of testing preparations. The actual testing period spanned three stages over eight weeks starting in November 2021, Ettlinger said on Friday. “First, we made sure the system was okay—we ran it on natural gas with the modifications we did to the plant, and then we ran it at a lower percentage of hydrogen. Eventually, we did the third test of up to 44%,” he said.

Ettlinger noted that the team’s original plan was to test hydrogen blends of up to 40%. However, as the team got closer to the end of testing, it had enough hydrogen, and all the systems were performing as or better than expected, he said. The actual testing time that involved injection of hydrogen “was closer to 12 hours,” and the third test of a 44% hydrogen volume spanned “probably a couple of hours,” he said.

Another Big Demonstration for GE’s Gas Turbines

For GE, which rolled out the LM6000 in the early 1990s, the project is another meaningful validation of the important role that hydrogen can play in lowering carbon emissions from power generation—while still providing crucial reliability and flexibility to the changing grid.

GE was part of a team that, in March, conducted another pioneering test to combust an initial blending of 5% hydrogen and 95% natural gas fuel at a GE 7HA.02 gas turbine at the 485-MW Long Ridge Energy Terminal combined cycle power plant in Ohio, a project purpose-built to transition from natural gas to hydrogen blends and ultimately be capable of burning 100% hydrogen.

While GE has combusted hydrogen in several gas turbine models, the Long Ridge test marked the first time a GE HA-class machine combusted hydrogen. GE is also spearheading hydrogen combustion tests in other models. Last year it announce it would pilot an F-class dual-fuel gas and hydrogen plant at EnergyAustralia’s existing 316-MW Tallawarra B Power Station in New South Wales, Australia. In September 2021, Territory Generation, a utility in Australia’s Northern Territory, separately said that it will install a GE TM2500 trailer-mounted aeroderivative gas turbine at the Channel Island Power Station, outside Darwin, to demonstrate the merits of hydrogen combustion.

The recent test at Brentwood marks a first big step for GE’s aeroderivative fleet, but it’s also a first triumph for GE’s capability to retrofit hydrogen capabilities on its existing fleet, Dr. Jeffrey Goldmeer, director of Emergency Technologies at GE Gas Power told POWER.

Owing to its history of more than 60 years of supplying gas turbine technology, more than half the global gas installed base is from GE. That’s roughly 7,000 gas turbines representing more than 800 GW of installed capacity in more than 120 countries.

GE LM6000 aeroderivative gas turbine, which now has the benefit of three decades of operational experience, is a quick-start, highly efficient technology that has widely been deployed for peaking operations. Today, it is highly suited to support renewable balancing. Derived from GE’s CF6-80C2 high bypass turbofan aircraft engine, the 46.1-MW simple-cycle, two-shaft turbine model installed at Brentwood is still one of the most fuel-efficient in its size class.

“The LM6000 unit located at NYPA’s Brentwood facility is a PC model, which means that it is configured with a singular annular combustor (SAC),” Goldmeer explained. “This is a diffusion combustion system that uses water injection for NOx emission control. Diffusion combustion systems typically also have the ability to operate on higher levels of hydrogen. The LM6000 has the largest installed base of any GE Aeroderivative gas turbine, so these learnings could be applicable to many other plants in the US. In addition, learnings can be shared with other SAC combustors (on LM2500 and LMS100 units), helping GE to accelerate our capability,” he said.

Goldmeer said the Brentwood pilot required no modifications to the gas turbine with the exception of instrumentation—temperature and dynamic pressure sensors—which GE added to monitor the combustion system during operation on the hydrogen fuel blends. “During operation on the hydrogen fuel blend, gas turbine operation was stable and the temperature and dynamic pressure data did not indicate any significant changes to gas turbine operation,” he noted.

Overall, the test demonstrated that “we can operate on blends of hydrogen and natural gas, and maintain NOx emissions at existing permit levels” with available technologies. At Brentwood, that entails a water-injected combustor and post-combustion after-treatment that includes selective catalytic reduction (SCR), Goldmeer said.

That’s highly promising, given that gas power is poised to take on a more significant role in balancing renewables as the energy transition unfolds. “In terms of the larger picture, we will need dispatchable power generation assets to support the electrical grid with increased installation of variable renewable energy systems, i.e. wind and solar,” he said. “Fast ramping aeroderivative gas turbines that are capable of operating on increased blends of hydrogen and natural gas could provide dispatchable power with lower carbon emissions that support grid reliability.”

LCRI Findings: Emissions Advantages Clear

According to LCRI’s key findings unveiled on Friday, the demonstration showed “expected trends,” including that CO2 emissions decreased as the hydrogen fuel percentages increased. “At 47 MWe, CO2 mass emission rates were reduced by approximately 14% at 35% by volume hydrogen cofiring,” LCRI’s report notes.

Significantly, at steady-state conditions, the plant’s current post-combustion emissions controls—including SCR and CO catalyst systems—were able to control stack NOx, CO, and ammonia slip levels below those limited by its New York State Department of Environmental Conservation (DEC) Title V regulatory permit. The demonstration achieved the reductions with “no known detrimental effects on the gas turbine operations,” NYPA said. “This result could prove consequential for power plant operators to begin testing and using hydrogen fuels—aiming to lower a facility’s carbon output—with minimal or no required modifications to plant systems.”

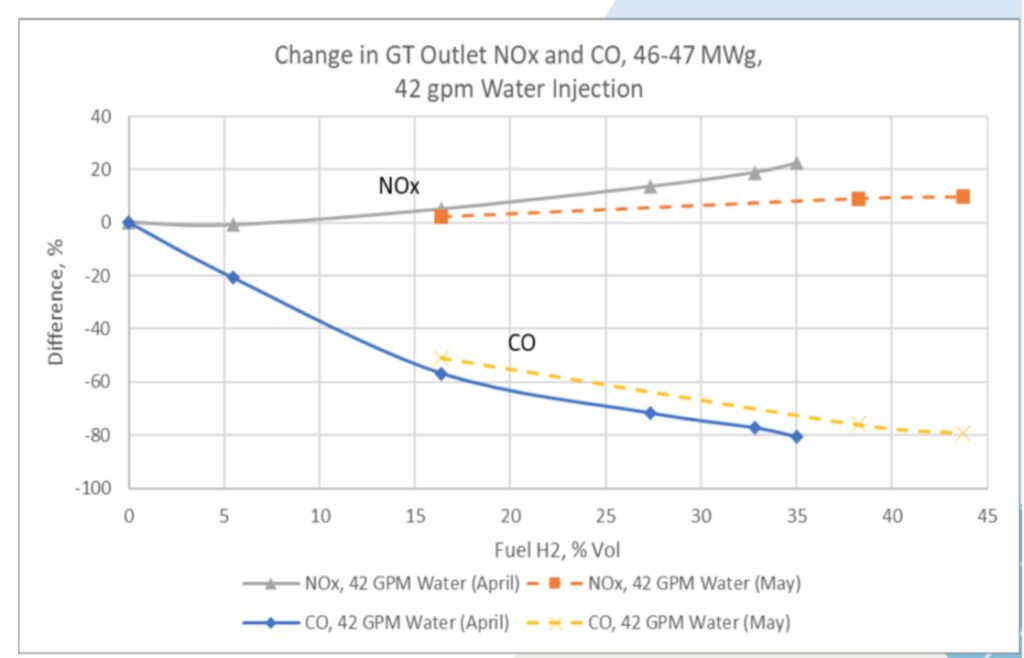

The study also explored impacts of NOx and CO emissions at the gas turbine outlet, upstream of the catalyst systems. It found that at steady water injection rates based on burning natural gas, gas turbine outlet NOx levels increased, and CO levels decreased as the volume of hydrogen in the blended fuel was increased. “By increasing water injection rates less than 20% by volume, [gas turbine] outlet NOx levels were maintained at a constant level as hydrogen fuel increased to greater than 35% by volume,” the report says. However, at higher levels of hydrogen, NOx levels increased by up to 24%.

What it means is that hydrogen co-firing could require LM6000 SAC operators to increase water injection almost linearly with hydrogen fuel percentage to maintain steady gas turbine outlet NOx levels. “It is important to note that this NOx increase observation is specific to LM6000 SAC technology and may not apply to dry-low emissions combustors,” the report notes.

CO levels also decreased substantially—as much as 88%—as the hydrogen volume increased during testing, even with increasing water injection rates for NOx control. That’s a significant finding that implies hydrogen cofiring (depending stack permit requirements) could allow LM6000 units “to operate across a wider load range without CO oxidation catalysts or with reduced volumes of catalyst, potentially lowering capital and [operation and maintenance] costs,” the report says.

GE’s Goldmeer highlighted this finding as a “great result.” It means hydrogen combustion at the LM6000 “has the potential to increase the emissions compliant turndown capability, which is normally limited by CO emissions,” he said. GE’s engineering teams are now “examining the data to determine what type of commercial offering might be included for plants that have interest in operating on blends of hydrogen and natural gas,” he noted.

Another key finding is that the turbine’s flame remained stable with increasing hydrogen fuel levels. As pivotally, “no significant changes to [gas turbine] operation were observed as measured by temperature and dynamic pressure sensors (which monitored combustion dynamics) during operation on hydrogen blends.” During the demonstration, gas turbine control was stable. It did not experience trips during variations in fuel composition, “provided that the lower heating value (LHV) and specific gravity data were transmitted to control software at the appropriate time.”

Challenges: Hydrogen Supply, Project Timing, Equipment Procurement

LCRI also offered some key takeaways for project developers looking to integrate hydrogen into their existing gas turbine fleet. One entails employing a collaborative design approach “early” to help identify and overcome integration challenges. At the Brentwood project, the “large number of teams involved with different design aspects of this project created situations where the design process was progressing at different speeds for each team. This led to rework late in the design process to ensure all the safety and operational requirements were met,” the report says. Design concepts must also take into account permit considerations, such as for the National Fire Protection Association, and allow enough time for permit exceptions, it notes.

A second crucial challenge with technical and market implications for gas generators looking at hydrogen as a replacement fuel involves maintaining a stable hydrogen supply. The Brentwood project had adequate volumes of hydrogen, which was trucked in on trailers, for the cumulative 12 hours during which testing was conducted. However, the team grappled with keeping the hydrogen supply stable, requiring constant manual adjustments to the hydrogen regulators located separately on each hydrogen trailer connection. “The team was able to make the system work with significant manual intervention that required constant monitoring and adjustment during the test,” the report says. “This would not be practical for normal plant operation.”

Other challenges include ensuring adequate natural gas supply pressure, which was inevitable as the hydrogen ratio increased. “As the hydrogen ratio increased, it was necessary to raise the [natural gas] supply pressure. This proved to effectively increase the limit of hydrogen that could be blended with [natural gas],” the report notes.

These issues may be overcome through further study. The most prominent hurdle industry faces if gas-powered hydrogen combustion is to thrive involves procuring adequate large-scale hydrogen supply and equipment to store it. Ettlinger noted the largest U.S. known tank containing hydrogen is NASA’s hydrogen storage tank, which holds 1.25 million gallons of liquid hydrogen. “The hydrogen in that tank would only provide four days of supply of hydrogen [at 100%] to Brentwood,” he said. “So again, getting back to probably one of the big themes is the supply of hydrogen is not something that can be ignored. It’s a significant issue as we move forward.”

LCRI also highlighted gaps in the foundational knowledge base for LM6000 cofiring, and issued a few recommendations to satisfy them. A notable recommendation involves hydrogen starts. While the demonstration’s gas turbine was always started up on natural gas, LCRI suggested that future investigations should perform starts with increasing hydrogen fuel. That will be key to establishing safe limits for startup, it said.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine)

The post NYPA, GE Successfully Pilot Hydrogen Retrofit at Aeroderivative Gas Turbine appeared first on POWER Magazine.