The Future Direction of Respiratory Protection

Credit to Author: Aaron Larson| Date: Sat, 01 Jun 2019 04:00:22 +0000

An estimated 5 million U.S. workers wear respirators. Employers are required to provide National Institute for Occupational Safety and Health (NIOSH)-certified respirators using a written respiratory protection program enforced by the Occupational Safety and Health Administration (OSHA). Design and manufacturing focus on fit, comfort, and ease of use across product lines incorporating advanced technologies, such as hands-free thermal imaging cameras and mounted facepiece displays to improve search-and-rescue capabilities. Uncertainties still exist about adopting International Organization for Standardization (ISO) guidance classifying respirators by performance class, work rates, fitting, and filter performance.

A respirator’s basic function reduces the wearer’s inhalation risk to hazardous airborne particles, gases, or vapors, and serves as the “last line of defense” when engineering and administrative controls are neither feasible nor sufficient. There are two primary respirator types:

- Air-purifying respirator (APR). Removes specific air contaminants by passing ambient air through an air-purifying filter, cartridge, or canister.

- Atmosphere-supplying respirator (ASR). Supplies the wearer with breathing air from a source independent of the ambient atmosphere. These include supplied-air respirators connected to an airline and self-contained breathing apparatus (SCBA) units carried by the wearer.

Respirators can be further defined by function. These include negative pressure (tight fitting); demand (admits breathing air into the facepiece by inhalation); pressure demand (maintains a positive pressure in the facepiece at all times and admits additional air into the facepiece during inhalation); and continuous-flow (steady airflow into the facepiece).

Following experience gained from World War I, the Department of the Interior’s U.S. Bureau of Mines (USBM) developed approval standards for industrial-use gas masks and filter canisters (Figure 1). The NIOSH, created by the Occupational Safety and Health Act of 1970, began certifying/approving respirators with the USBM in 1972. With the release of Title 42 of the Code of Federal Regulations, Part 84 (42 CFR 84), “Approval of Respiratory Protective Devices,” in June 1995, and abolishment of the USBM in 1996, NIOSH became the sole approver of respirators. The approval program was transferred to the newly created National Personal Protective Technology Laboratory (NPPTL) in 2001. NIOSH is part of the U.S. Centers for Disease Control and Prevention within the Department of Health and Human Services.

A summary of NIOSH/NPPTL Evaluation and Approval Program requirements include:

- Respirator design and results (engineering drawings, specifications, and performance test results).

- Applicant’s manufacturing quality assurance/quality control system.

- User instructions, packaging, and component labels.

- Post-approval manufacturing site audits.

- Public and manufacturer notices.

- Revoking Certificate of Approval for cause.

The Science of NIOSH-Certified Respiratory Protection

POWER interviewed Jeff Peterson, Conformity Verification and Standards Development branch chief, and Respirator Approval Program administrator; and John Powers, Evaluation and Testing branch chief. Peterson discussed how NIOSH follows 42 CFR 84—a minimum performance standard—which does not restrict a respirator’s design or limit innovation by a particular manufacturer. “We try to evaluate innovative designs that come to us by setting forth performance standards for each of the types of respirators,” Peterson said. “The regulation gives us authority if we need to develop unique or novel procedures to evaluate a characteristic that is not addressed,” he added.

When a manufacturer develops a new design, it collects performance data either at its facility or from a third-party laboratory. Powers’ group conducts NIOSH performance tests to validate data submitted by the manufacturer, such as fit, filter and cartridge efficiency, breathing resistance, and valve leakage. Therefore, “NIOSH-certified” reflects a complete respiratory protection system (that is, filtering device and respirator together) passing minimum performance standards simulating worst-case use. This complete system is added to the all-inclusive Certified Equipment List (CEL). Peterson commented that there have been more than 9,000 products evaluated and listed in the CEL since the Respirator Approval Program’s inception.

In addition to NIOSH in-house testing to verify performance requirements, Powers said, “We will go to their manufacturing facility and do a review of their quality system to make sure that it is still meeting all the requirements that they put forth and submitted for the approval.” Nonconformances identified either by NIOSH or the manufacturer are corrected by the manufacturer.

NIOSH neither provides accreditation, nor specifies manufacturer accreditation, because most manufacturers pursue certification on their own, such as ISO 9001 (see sidebar). However, NIOSH can remove the CEL approval number when requirements are not met. Nevertheless, if the respirator is neither on the CEL nor has the required markings, it has not been certified by NIOSH for occupational use.

Additional Respirator Testing to Consensus StandardsWhile NIOSH approval serves as a foundation for all respirators, certain applications require approvals beyond 42 CFR 84. Given the extreme nature of the work environment, specific criteria applicable to firefighting personal protective equipment can be tested—in addition to NIOSH—using National Fire Protection Association (NFPA) consensus standards. A NIOSH-approved SCBA via 42 CFR 84 is often referred to as an “Industrial SCBA” to delineate from an NFPA-compliant SCBA tested against environmental and operational emergency response requirements using NFPA 1981:2019 “Standard on Open-Circuit Self-Contained Breathing Apparatus (SCBA) for Emergency Services.” Testing includes:

Beginning with NFPA 1981 (2007 Edition), SCBAs intended for emergency service use have required NIOSH approval as chemical, biological, radiological, and nuclear (CBRN) SCBAs, according to the Statement of Standard for NIOSH CBRN SCBA Testing. The CBRN certification provides requirements for Chemical Warfare Agent (CWA) Permeation and Penetration Tests, including 151 toxic industrial chemicals and terrorism agents. Energy sector companies may opt to use CBRN-certified respirators, which are likely to be used in high-hazard environments. —Brad Harvey is senior application engineer, Fire Service and SCBA, with 3M Personal Safety Division. |

Respiratory Protection Enforcement

According to OSHA’s respiratory protection standard, 29 CFR 1910.134, “Respiratory Protection,” the employer designates a qualified administrator—typically a safety officer or industrial hygienist—to manage the program using written procedures.

Respiratory Protection Program requirements include:

- Selecting NIOSH-certified respirators and filtering devices based on hazards, such as particulate and oxygen-deficiency protection capabilities.

- Medical evaluation verifying the worker’s ability to wear a respirator before fit testing.

- Qualitative or quantitative fit testing using the same respirator make, model, style, and size.

- Training, maintenance, cleaning, and storage schedules.

OSHA’s view of respirator performance is by assigned protection factors (APFs). Respirator function can significantly influence the APF; 50 for a full-facepiece APR (negative pressure), compared to 10,000 for a full-facepiece SCBA unit (pressure demand).

Fit, Comfort, and Ease of Use

To get a manufacturer’s viewpoint, POWER interviewed Don Rust, application engineering specialist with 3M Personal Safety Division. Rust said, “There is a focus on fit, comfort, and ease of use across all respiratory protection product lines.” For example, certain headgear for NIOSH-approved respiratory protection systems integrate face shields and head protection to improve the user experience.

“Often, by combining personal protective equipment into a comfortable and user-friendly system, we can achieve greater customer acceptance and in turn, they may experience fewer injuries and illnesses and even see improvements in productivity,” Rust said.

This is also being applied to confined space entry systems. Incorporating an SCBA into a harness system makes it streamlined for easier escape or rescue, if needed (Figure 2). Also, cross-cutting applications are deployed whenever possible, such as incorporating military technology into respirator facepieces (Figure 3, 4, and 5).

|

| 2. Respiratory protection and harnesses can be combined to assist workers while ascending and descending from elevated platforms. Courtesy 3M |

|

| 3. The AV-3000 HT facepiece shown here has a 3M Scott sight thermal imaging camera (TIC) attached. Courtesy: 3M |

|

| 4. A miniaturized display is mounted inside the facepiece to improve search-and-rescue capabilities. Courtesy: 3M |

|

| 5. Battery life (green) is shown on the in-mask display (IMD). Information is recorded for later review. Courtesy 3M |

Other advancements include:

- Communication. Bluetooth push-to-talk fetures and speaking diaphragms to amplify a user’s voice.

- Geolocation. Sensors prohibiting entry unless wearing the required personal protective equipment.

- Monitoring. Real-time sensors inside filter cartridges signaling change-out (instead of one-time use) and chemical/particulate saturation warnings (instead of color indicators).

- Sustainability. The 3M Disposable Respirator Stockpile Maintenance Program offers disposal options for aging and expired respirators. The program allows recycling (components are recycled into new plastic products); waste-to-energy (used as power generation fuel); and donation (products with 12 months of shelf life remaining can be donated and used until expiration).

Harmonization

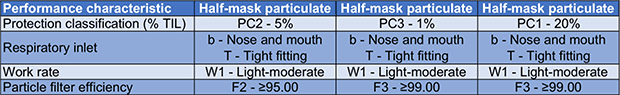

Rust mentioned that although respirators are used globally, and even if they meet 3M, NIOSH, and European standards, adopting harmonized performance, markings, labels, and packaging requirements—and even terminology—becomes challenging (Table 1).

The U.S. system uses design, NIOSH-certified testing, and OSHA APFs, compared to ISO/TS 16975-1:2016 human factor and laboratory-based total inward leakage (TIL) percentages. The ISO standard includes:

- Six protection classes (PCs). TILs range from PC1 (20%) to PC6 (0.0001%).

- Four work rates. From light-moderate work (W1) to maximal work effort (W4).

- Respiratory-interface classes. Tight-fitting (T) or loose-fitting (L).

- Five particle filter efficiencies. F1 (≥80.00%) to F5 (≥99.99) or chemical cartridge type and capacity.

For example, Table 2 lists three half-facepiece respirators having different ISO PCs.

Also, three different RPDs—a full-face assisted, full-face unassisted, and half-mask assisted—can have identical PCs, work rates, and uses, but different particle filter efficiencies (F2, F3, F4). Additional differences include that the lighter full-face unassisted RPD lacks a motor/blower system, while the half-mask assisted RPD lacks eye/face protection.

The PC laboratory tests establish a consistent approach for developing protection levels. However, they do not necessarily reflect workplace activities, airborne hazards, and differ significantly from NIOSH and OSHA respirator nomenclature. Adopting this new classification system would involve the U.S. government’s rulemaking process, requiring public notice and comment, and is likely many years away. If harmonization is successful, the next time a tight-fitting, full-face PAPR (APF=1,000) with a P100 high-efficiency particulate air (HEPA) filter is needed, it may require a full-face, assisted PC4 W2 cT F4 RPD.

—James M. Hylko (JHylko1@msn.com) specializes in safety, quality, and emergency management issues and is a frequent contributor to POWER.

The post The Future Direction of Respiratory Protection appeared first on POWER Magazine.